December 2024

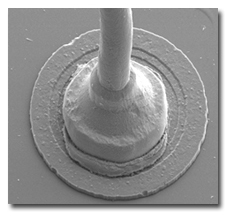

Copper Bond Wire

Copper wire bonding in semiconductors has become increasingly popular due to its cost-effectiveness and superior performance characteristics compared to traditional gold wire bonding. As the semiconductor industry continues to push the boundaries of miniaturization and efficiency, copper's excellent electrical and thermal conductivity make it an ideal choice for high-performance applications. However, the transition to copper wire bonding is not without its challenges.

Copper wire bonding in semiconductors has become increasingly popular due to its cost-effectiveness and superior performance characteristics compared to traditional gold wire bonding. As the semiconductor industry continues to push the boundaries of miniaturization and efficiency, copper's excellent electrical and thermal conductivity make it an ideal choice for high-performance applications. However, the transition to copper wire bonding is not without its challenges. Take a look at some of our most frequently asked questions:

Q: Why do manufacturers use copper bond wire?

A: Copper bond wires provide:

- Lower price

- Better electrical and thermal properties

- Higher bond break force

- Copper has a higher elongation than gold which means copper can withstand plastic deformation longer

Q: What are some concerns associated with copper bond wires?

A: Concerns include:

- Easily oxides in air - typically requires N2 or special flow of forming gas during manufacturing

- Cu is harder - requires an optimal bonding process

- Quality/Reliability concerns:

- Bond pad aluminum deformation (splash)/cratering/cracks under the bond Cu ball bond interface corrosion

- IMC (intermetallic dielectric) cracking

- Peeling of the bond pad interface - bond lifting is a major reliability concern

- Typically halogen free special molding compound required for Cu wire products to prevent corrosion of wires

Q: What are the issues with decapsulation of a copper bond wire part?

A: Acid will dissolve the copper bond wire very quickly unlike gold or aluminum wires. A special decapsulation technique is need for decapsulation of copper bond wire parts.

Q: What are the best practices for decaping a copper bond wire plastic part?

A: Take the following into consideration:

- It is best to use laser ablation followed by minimal acid to decapa copper bond part

- It is recommended that before the laser ablation process, smaller dimension devices may need to be mounted on an appropriate substrate of media

- It is recommended to pre-bake the device right before laser ablation at some elevated temperature

- Knowing the material composition and construction of the device before laser ablation is immensely helpful

- It is considered to be a best practice to understand the recipe of decapsulation as it will vary package type by package type.

Have more questions? Let us know: sales_inquiry@integra-tech.com