September 2023 FAQ: Ribbon Bonding

Ribbon bonding offers an alternative to wire bonding and tape automated bonding (TAB). The process achieves the required density of interconnections for both inner and outer bonds. At the same time, it eliminates the need for either bumped chips or tape, and it avoids the tooling costs normally associated with TAB.

Ribbon bonding offers an alternative to wire bonding and tape automated bonding (TAB). The process achieves the required density of interconnections for both inner and outer bonds. At the same time, it eliminates the need for either bumped chips or tape, and it avoids the tooling costs normally associated with TAB.

Take a look at some of our most frequently asked questions:

Q: Does Integra offer Ribbon Bonding?

A: Yes, Integra has the HYBOND 572A Vertical Feed, Deep Access Ribbon Bonder.

Q: What are the ribbon sizes offered?

A: Up to 1 mil x 10 mils ribbon wire Gold or Aluminum.

Q: What are the benefits of ribbon bonding?

A: Benefits:

- Enhanced Electrical Performance

- Higher Current Carrying Capacity

- Improved Thermal Management

- Reliability and Durability

Q: When would I use Ribbon Bonding?

A: Ribbon Bonding enables a significant reduction in the resistance and inductance of the connections, leading to improved electrical performance of the assembled electronic devices. This is especially crucial for high-frequency applications where signal integrity is critical.

Q: What are some of the key attributes of the system?

A: Attributes:

- Ultrasonic Power Range: 0-1 watt on low setting (default), 0-2 watts on high setting

- Bond Time Range: 10-400 mSec

- Bond Force Range: 15-150 grams

- Temperature Control: Ambient to 250C

Have more questions? Let us know: sales_inquiry@integra-tech.com

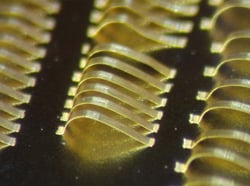

*photo F&S BONDTEC