December 2023 FAQ: Die-to-Wafer Bonding

Take a look at some of our most frequently asked questions:

Take a look at some of our most frequently asked questions:

Q: Does Integra offer die-to-wafer bonding?

A: Yes we do, primarily for SiPho typically utilizing a 3-5 die onto an SOI wafer. We use atmospheric type instead of the conventional vacuum type plasma.

Q: Are there any concerns with Die-to-wafer bonding?

A:

- Surface contamination kills bond ability

- Surface smoothness - < 0.5nm

- Preplanning during fabrication is key

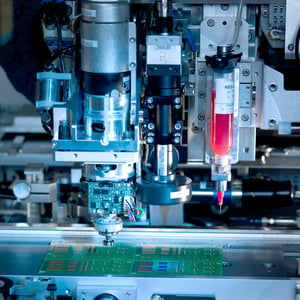

Q: What equipment does Integra use?

A: BESI 2200 Evo Plus

Q: What type of environment do you have for these processes?

A: Class 1k cleanroom / Class 100 equipment

Q: What is the throughput of the system?

A: Bonding capability up to 500 dies per hour

Q: What is the placement Accuracy?

A:

- Placement accuracy <XY>: +/- 7µm (35µm w/o pattern on die/wafer) - Placement accuracy <theta>: +/- 0.3⁰deg

- AOI prior to die placement = higher yield

- Optional Laser mark for die traceability

- FA Metrology: CSAM / Pull Test / *Surface Roughness / *SEM. (*) = Outsourced

Q: Bonding Materials:

A:

-

Material: Si / Silicon-On-Insulator (SOI)

-

Wafer size: 50~200mm

-

Thickness: 0.4~2.0mm

-

Surface roughness: Ra <0.5nm

-

Temperature: 200~1000⁰C. / Nom. 550⁰C

Q: What are the Die parameters?

A:

-

Material: InP, GaAs , BTO & TFLN (devel)

-

Die size: 0.5~50mm

-

Thickness: 0.1~7.0mm

-

Surface roughness: Ra <0.5nm (CMP req.)

-

Edge chipping: <5µm

-

Temperature: 200~1000⁰C. / Nom. 550⁰C

Have more questions? Let us know: sales_inquiry@integra-tech.com