July 2020 FAQ: Dicing and Die Prep

Integra provides quick-turn and volume die prep to many customers. Here are some of our frequently asked questions:

Q: What does Die Prep Encompass?

A: Die prep encompasses all processes that take an IC from a wafer after test and into die form prior to assembly. Primary die prep processes are: Backgrind, Saw, Pick, and Inspection

A: Die prep encompasses all processes that take an IC from a wafer after test and into die form prior to assembly. Primary die prep processes are: Backgrind, Saw, Pick, and Inspection

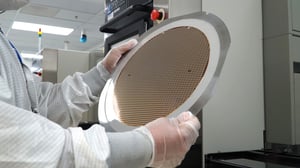

Q: What is wafer backgrind?

A: Wafer thinning, or backgrind, is the process of removing material from the backside of a wafer to a desired final target thickness

Q: What are the most common forms of backgrind?

A: The most common methods of wafer thinning are mechanical grind, wet etch, and chemical-mechanical planarization (CMP)

Q: What kind of backgrind does Integra use?

A: Mechanical grind

Q: What does microgrind or polish do to my wafer?

A: Die strength and smoothness can be increased based on grit/slurry selection (increasing smoothness), while also decreasing warpage and subsurface damage

Q: What are the most common types of wafer singulation?

Q: What are the most common types of wafer singulation?

A: The most common methods of wafer singulation are mechanical dicing, laser dicing, scribe and break, and dice before grind (DBG)

Q: What determines the best method for wafer singulation of my wafer?

A: Material type, wafer thickness, and street width are the most critical factors in wafer singulation when determining the optimal process method

Q: What are some keys when considering street widths of my wafer and subsequent dicing?

A: The following are keys when considering Street Width

- A typical street width for mechanical dicing is in the neighborhood of 80um

- Street width governs the blade/kerf width

- Total thickness (including bumps) determines blade exposure

- Blade exposure is restricted by blade width

- The narrower the blade the smaller the exposure

- Therefore, for wafers with narrow streets thinning is required

Q: I have a multi-project wafer, what are some considerations?

A: The following are considerations

- Multi-project wafers require the indexing to be consistent across all die in a reticle in order to singulate without sacrificing die

- Inconsistent indexing between die in a reticle would require die to be sacrificed, or cut through, in order to salvage the target die

- If all die in an inconsistent reticle are required to be saved, then remounting is necessary