Die Preparation

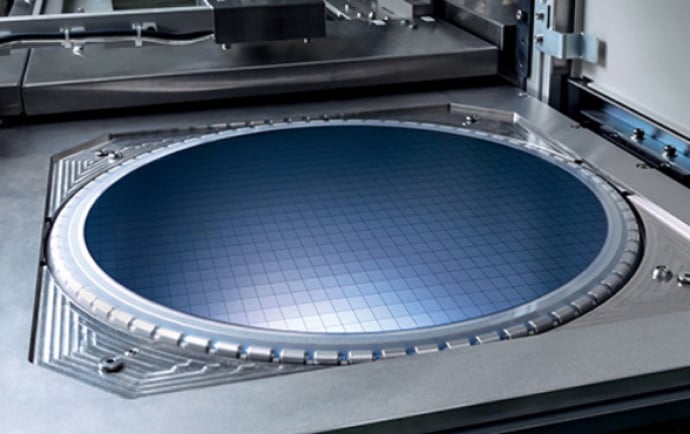

Wafer Thinning & Polishing

We specialize in ultrathin precision wafer thinning, all the way down to 25 µm. Our facilities can handle bumped wafers of various bump heights and pitches, and we stock a diverse assortment of front-side tapes to ensure optimal protection for wafers during processing.

Our proprietary dry polishing service removes most subsurface damage that comes with wafer grinding under 100 µm, enabling safer die handling and higher yields.

Materials

We work with these wafer materials:

- Glass

- Silicon

- Quartz

- Sapphire

- Laminates

- Piezoelectric

- Gallium Arsenide (GaAs)

- Silicon Germanium (SiGe)

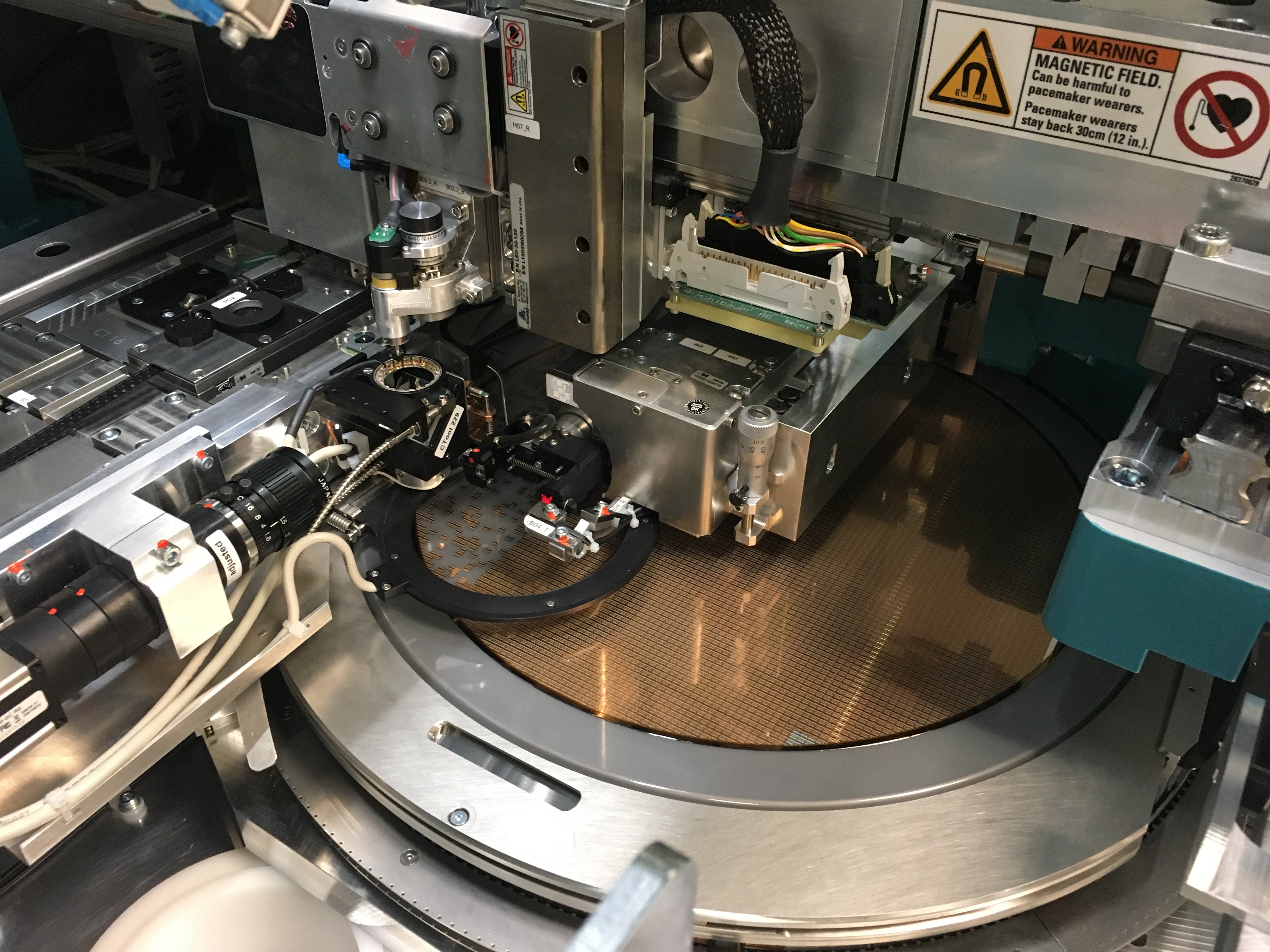

Wafer Dicing

Our in-house engineers have carefully researched and isolated the most common causes of die chipping, low die strength and poor yields. At the end of the day, it usually comes down to subpar dicing.

To avoid that, we use world-class, fully automatic DISCO wafer dicing systems. This allows us to handle wafer sizes ranging from mere fragments to 300 mm in diameter, with cut lines as small as 15 µm.

Dice Before Grind (DBG)▼

Die Attach Film (DAF)▼

Custom Parameters▼

Complex Die Patterns▼

Cleanliness & Electrostatic Discharge Elimination▼

Pick & Place

We offer automatic pick and place services to place your dice in:

- GelPack

- Waffle packs

- Tape and reel

Manual pick and place is also available for:

- MEMs

- Topside handling

- Die-sensitive products

- Unpassivated products

- Die picking from wafer maps

- Ultraclean processing of optical or image chips

Individual die ID recording is also available on demand.

Die Inspection

Integra Technologies is the United States’ leading provider of high- and low-power die visual inspection services for RFID, hearing aid, defibrillator and heart pacemaker manufacturers. We process tens of millions of die per month, carrying out both manual and automated visual inspections using the latest August Technology and Camtek systems to the following specifications:

- Commercial

- Medical Electronics

- Method 2010 Cond A & B

- MIL-STD-883 (Class B or Class S)

- Customer-specific requirements

Assembly Service Guide

Learn how to make your products cost effective and ready for manufacture with this detailed guide.