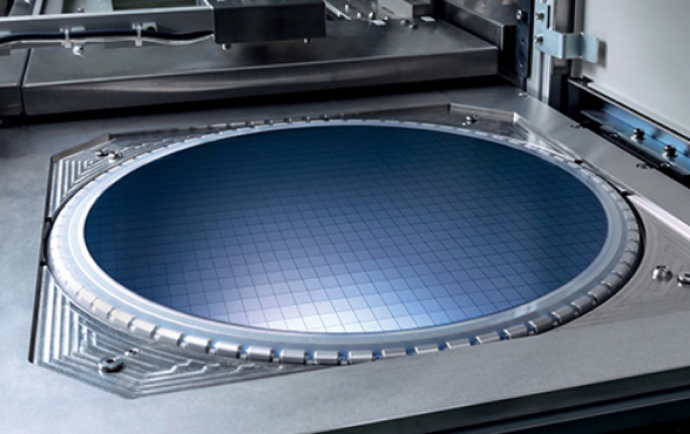

Dice Before Grind (DBG) is a wafer singulation method where the wafer is partially cut (diced) into individual chips before the wafer thinning (backgrinding) process. After dicing, a protective tape or material holds the die in place while the wafer is thinned down to its final thickness.

The method is used to reduce stress and cracking compared to traditional “grind before dice” methods. It also allows handling of ultra-thin wafers that would otherwise be too fragile to dice after thinning. DBG also improves die strength and yield for advanced packaging applications like 3D ICs, SiP, and mobile devices.

Explore some of our commonly asked questions:

Q: What does “ dice before grind” mean in wafer processing?

A: “Dice before grind” refers to the inspection and preparation steps performed on semiconductor wafers prior to the backgrinding process, which thins the wafer to the required thickness. These steps help ensure the wafer can withstand thinning without introducing damage or defects.

Q: Why is before-grind inspection important?

A: Because wafers are fragile, any pre-existing cracks, scratches, or particles can worsen during backgrinding. Inspecting before grind helps detect issues early, reducing the risk of wafer breakage and yield loss later in production.

Q: What processes are typically included in before-grind preparation?

A: Key processes often include:

- Wafer cleaning to remove particles and contaminants

- Surface inspection (optical or automated)

- Taping or applying protective film to support the wafer during thinning

- Defect mapping for process control

Q: How does before-grind preparation improve yield?

A: By protecting wafer surfaces and identifying defects early, before-grind steps reduce the chance of catastrophic wafer loss during thinning, dicing, and packaging. This directly improves final device yield and lowers overall manufacturing costs.

Q: What technologies are used for before-grind inspection?

A: Optical inspection systems, automated defect review tools, and in some cases SEM (scanning electron microscopy) are used to detect even microscopic cracks or particles that could compromise wafer integrity.

Q: Who benefits from strong before-grind processes?

A: Any manufacturer producing thin die for advanced packaging — such as mobile, automotive, medical, and high-performance computing — benefits, since reliability and mechanical strength are critical for smaller, thinner devices.