ESD Services

Integra Technologies’ ESD Services cover all aspects of electronic device reliability qualification with fast turnaround time.

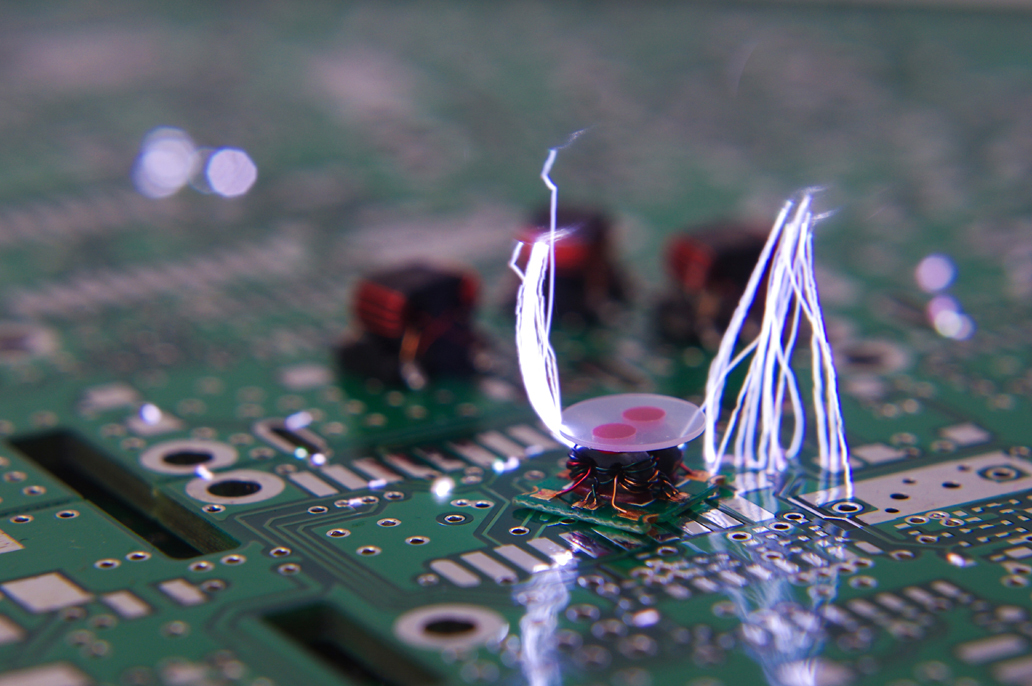

Electrostatic discharge (ESD) testing is performed early in the qualification cycle, usually at first silicon. Evolution in technology and applications (RF, analog) constantly drive new configurations, usage patterns and failure modes.

A Proven Methodology

Our standard flow includes:

- Identification of required tests to appropriate specs

- Selection of fixturing

- Test execution

- Reporting

We support all types of electrical stresses:

- HBM/MM

- CDM

- Latch-up

Wide Range of Supported Standards

IC level: JEDEC, AEC, ESDA, ANSI

Market specific: MIL, AEC

Fast Turn-around Time

Since concerns over ESD reliability usually come early in the development cycle, typically after first silicon, Integra offers very fast turn-around times, giving real-time feedback to design and product teams.

This is made possible by our very comprehensive inventory of fixtures and adapters—more that 850 of them. Most packages can be accommodated by one of our existing boards/sockets, alleviating the need for extra design time and/or NRE.

Consulting and Audits

Beyond stressing devices, our experts will help you understand the best stress strategies and set-up for your mission profile(s), as well as consult with you on the best design strategies for ESD protection.

ESD Services Standards:

- ESD-HBM(ANSI/ESDA/JEDEC-JS-001-2017,ESDAANSI/ESDSTM5.1,MIL 883-3/3015-9,AECQ100-002 RevE

- ESD-MM(JEDECJESD22-A115C, ESDA ANSI/ESD STM5.2, AEC Q100-003 RevE

- ESD-CDM (JEDEC JESD22-C101F, ESDA ANSI/ESD STM5.3.1, AEC Q100-011 RevD, ANSI/ESDA/JEDEC-JS-002-2018)

- Latch-up(JEDECEIA/JESD78E, ESDAANSI/ESD SP5.4, MIL 883-3/3023.2,AECQ100-004 RevD