September 2021 FAQ: Die Attach

Take a look at some of our most frequently asked questions:

Q: What type of die attach does Integra do?

Q: What type of die attach does Integra do?

A: Die attach using various conductive, non conductive epoxy and DAF ( Die-Attach-Film) as well as:

Die attach of ceramic, hybrid packages using silver glass adhesive

Eutectic die attach using Au98/Si2 & Au80/Sn20 preforms (capital required)

Integra will need to verify availability of preform sizes vs. die size

Sintered Silver also available under Engineering Control

Q: What are your X/Y placement accuracies?

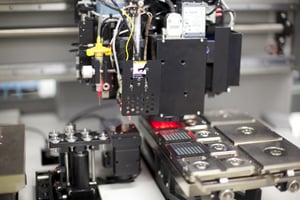

A: MAT- 6400 die bonder: DIE ATTACH +/-5um @ 3sigma - Application dependent (+/- 10 um after die attach cure)

Data-con 2200 APM die bonder:

DIE ATTACH +/- 10 um (+/- 15 um after die attach cure)

Q: What die sizes can you work with?

A: 750um to 40mm typical and larger or smaller with engineering review

Q: What kind of bond line thickness control does Integra have?

A: Pressure and time control (for epoxy) : Target BLT +/- 12.5 um (die size dependent) Height or distance control (for silver glass) : Target BLT +/- 12.5 um

Q: For manual die attach how do you control bond line thickness?

A: We recommend the use of glass bead spacers for BLT control

Q: What kind of fillet and epoxy coverage do you guarantee?

A: We guarantee to meet or exceed MIL-STD-883, Methods 2010, 2012 and 2030